News

Recommended Products

Contact Us

Contact Person: Cindy Zhu

TEL:+86 13418453374

What are the design features of the centering machine?

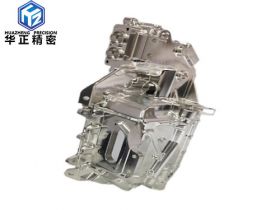

The full name of the centering machine is the centering CNC lathe, referred to as the centering machine, the scientific name definition: the spindle mobiles CNC lathe. In the market, it is called Swiss precision automatic lathe, and in the Chinese market, it is also called slitting CNC lathe. Because of its standard configuration with a side power head, it is also called a walking center turning and milling compound lathe.

The difference between CNC machine and CNC lathe. CNC machine is one of the equipment of CNC lathe. The traditional CNC lathe is mainly based on the cutting mode, which is called a cutting machine. The product is not held in a single clamping position, and the product is processed by the rotation of the spindle and the movement of the tool; The movement and rotation of the main shaft process the product and support multiple feedings.

Therefore, compared with the tool-type machine tool, when the centering machine is turned, the bar material is fed axially through the center guide sleeve, and the cutting point of the tool is close to the mouth end of the guide sleeve, which has good rigidity and eliminates the bar material under the cutting pressure of the tool. Deformation ensures the accuracy of the parts, and has the advantages of processing slender shaft parts. However, under normal circumstances, the centering machine only supports batch processing of long bars; it cannot be processed like a single-piece short material like a cutting machine. At the same time, because the bar material needs to pass through the entire main shaft, chuck, and guide sleeve, the walking machine has higher requirements on the straightness and ovality of the raw material.

Since the structure of the centering machine is different from that of the traditional CNC lathe, the processing efficiency and processing accuracy of the centering machine are higher than those of the CNC lathe. The machine adopts two-axis arrangement of tools. This design greatly saves the processing cycle time. By shortening the tool exchange time between the arrangement of tools and the opposite tool table, the overlapping functions of multiple tool tables and effective axis movement of thread chips are realized. , The direct spindle indexing function during the secondary processing shortens the actual and empty travel time. In the machining process of the spindle and the workpiece clamping part, the chip tool has always played a very important role, which provides a strong guarantee for constant machining accuracy. As far as the centering machine market is concerned, 38mm is its maximum processing diameter, which makes the centering machine have a great advantage in the precision shaft processing market. This series of machine tools can also be equipped with an automatic feeding device to realize fully automatic production of a single machine tool, reducing labor costs and defective products in the production process, and can be used to produce large quantities of precision shaft parts.

Prev: What are the types of CNC precision parts processing?

Next: Precautions for CNC precision machining

Back